Hulls joint & Bridgedeck building

| Before starting with hulls joint and bridgedeck building, it is very important to align perfectly the two hulls, controlling the parallelism, the stems line up, the levelling from the hulls water lines and hulls sides. To do this I put two big and strong iron box beams (section of 20x10 cm) crosswise the hulls, under the wood supports. After adjusting the plane between the two box beams, it was very easy to adjust and maintain the plane between the water lines using a water level. for the alignment was necessary many checks and little adjustments for centrelines parallelism and diagonals from respective stems and sterns. | ||

| One of the beam builded in advance on my workshop |

|

|

|

|

|

|

A frame support was prepared to sustain bridgedeck floor. | |

|

|

|

| Only one side of the second hull was finished in order to facilitate the joint operations with the beams. |

|

|

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

Building the bridgedeck roof support frame |

||

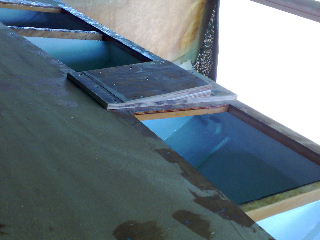

Bottom roof panels in position |

||

|

||

|

||

Bridgedeck roof in position after strip planking and biaxial sheeting. |

||

|

||

|

||

Cover removed to have more space to work on the top and to be prepared for winter time (October 2009) |

||

|

||

Cockpit and engine cases building |

||

|

||

| Starting of interior fornitures building | ||

|

||

|

||

|

||

|

||

|

||

King mast in position |

||